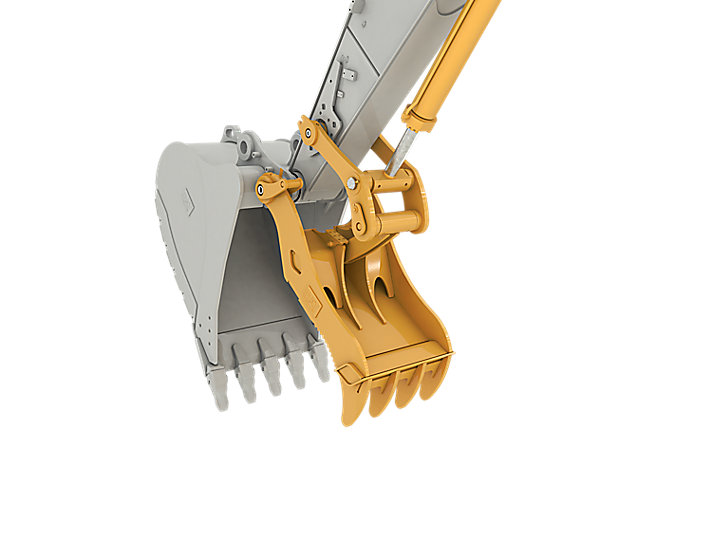

Tackle your jobs with a complete Cat solution. Cat attachments are not just accessories – they are essential tools that define what your machine can do. When you pair a Cat excavator with Cat attachments, you unlock a fully integrated system built for performance, durability, and efficiency. Whether you are clearing land, breaking concrete, or compacting soil, the right attachment transforms your excavator into a powerful, multi-purpose tool ready for any challenge. Depending on your project or application, you could benefit from excavator attachments such as:

- Buckets: Handle everything from digging and grading to cleanup and debris removal with your excavator. Cat offers general duty, heavy duty, extreme duty, and severe duty buckets, as well as specialized designs for ditch cleaning, rock, and finishing work. Reinforced edges and wear-resistant materials ensure long-lasting performance in tough conditions.

- Demolition and Sorting Grapples: Tackle larger debris or precisely sort materials into piles. These grapples are engineered for accuracy in demolition and material sorting, handling concrete, rebar, wood, and mixed debris. High clamping force and agile movement make them ideal for primary and secondary demolition and recycling operations.

- Orange Peel Grapples: Built for scrap and bulk material handling, Orange Peel Grapples excel with irregular, heavy loads like metal, rock, and waste. Their hydraulic tines provide superior grip and penetration. High-capacity and continuous rotation are perfect for scrap yards and transfer stations. Cat offers these grapples with a choice of different shell designs and tine options suited to various applications.

- Hammers: Break concrete, rock, and steel with up to 1,000 blows per minute. Built for high-production demolition, quarrying, and construction, they offer powerful impact energy and consistent performance. Their durability and low-maintenance design make them essential for demanding breaking applications.

- Scrap and Demolition Shears: Rotating shears provide precision cutting for metal structures, pipes, rebar, and scrap, making them ideal for demolition and recycling. Their powerful jaws and fast cycle times ensure clean cuts and high productivity. Built for durability, they excel in heavy-duty steel processing.

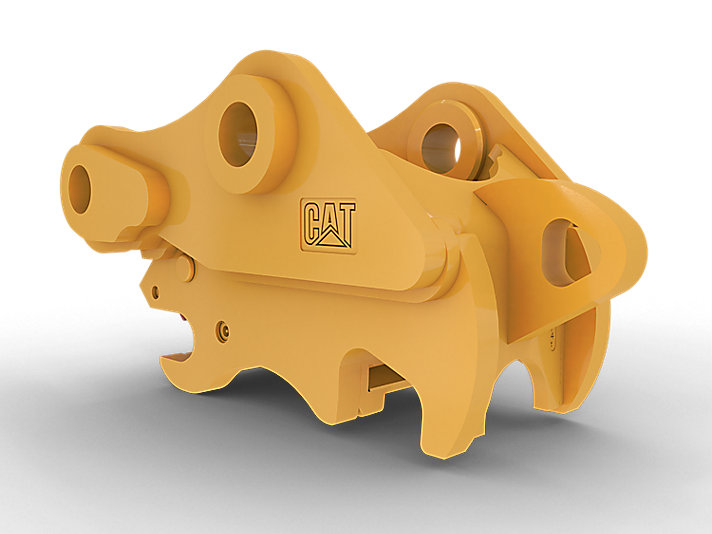

- Tiltrotators: Tiltrotators provide 360° rotation and 40° left/right tilt functionality, allowing attachments to move with unmatched precision and flexibility. This flexibility transforms your machine into a multi-functional tool capable of working from virtually any angle without repositioning. Ideal for grading, trenching, and complex excavation work, they deliver multi-angle control for tight and confined spaces.

Cat attachments are engineered to maximize your excavator’s productivity, helping you get more work done with greater efficiency and confidence. Choosing the right attachment is not just about compatibility, it is about unlocking your machine’s full potential while avoiding equipment damage or safety risks. Connect with your Cat Dealer to find the optimal attachments for your specific machine and application needs.