Why Cabin Air Filter Replacement Matters

Estimated read time: 5 minutes

Heavy equipment cabs are designed with features that help operators work safely and efficiently with less fatigue. However, a growing body of evidence indicates that breathing contaminated air filled with dust particles can be very harmful. That’s why Caterpillar is focusing on technology that improves operator cabin air safety.

Know The OSHA Recommendations

Dust particles of all kinds and sizes are present wherever heavy equipment operates. Machines such as excavators, graders and dozers can stir up clouds of particles. According to the Occupational Safety and Health Administration (OSHA), many of these particles are small enough to be inhaled or “respirable” and might pose serious health risks.

Crystalline silica dust, in particular, is associated with certain diseases. OSHA regulates exposure through its silica standard for clean cab air.

How Does OSHA Define Clean Cab Air?

For cab air to be considered clean, it must meet the high safety standards that help protect heavy equipment operators while they’re working inside a machine’s cab. The air is filtered before entering the machine’s HVAC system. Once inside the cab, that air is then continuously filtered, improving the overall air quality inside heavy equipment.

The goal of the precleaning and filtering processes is to remove the debris and dust. This includes dangerous, “invisible” silica particles that can bypass the human body’s defenses (such as nose hair, bronchial tubes, etc.) and settle into the lower lungs. OSHA has concluded that workers who inhale crystalline silica particles are at an increased risk of developing serious silica-related diseases, including silicosis — which is an incurable lung disease that can lead to disability and death — lung cancer, chronic obstructive pulmonary disease (COPD) and kidney disease.

OSHA recommends three steps to achieve clean cab air:

Allow only filtered fresh air into the HVAC system of the cab.

Continuously filter air as it circulates through inside the cab.

Monitor cab pressure to ensure positive pressurization.

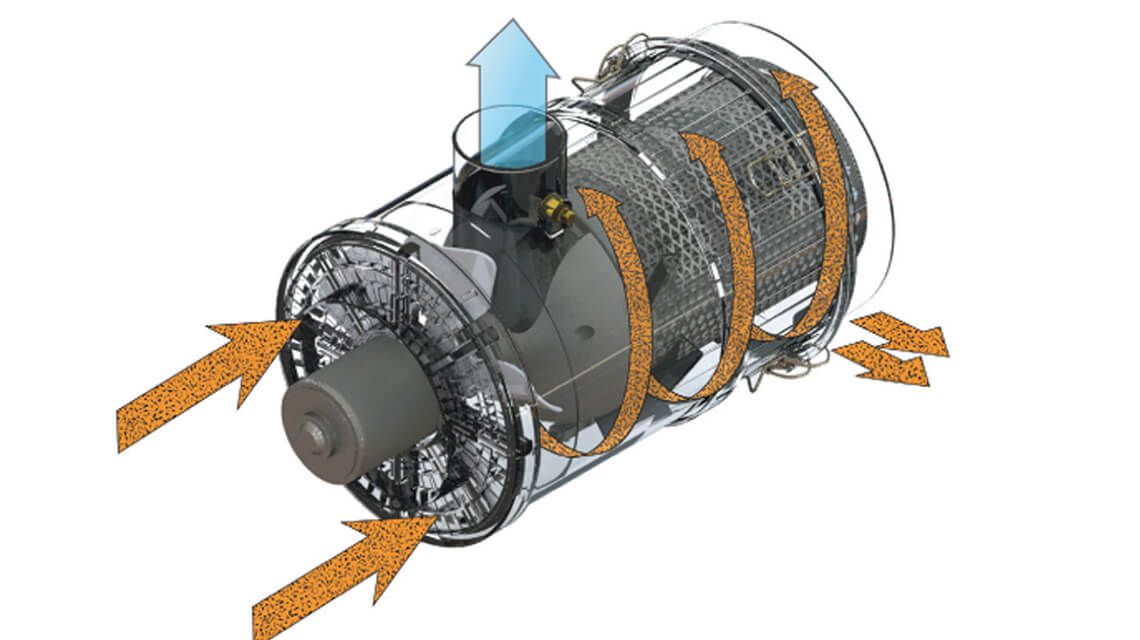

Cat® Advanced Cabin Filtration System (ACF)

The Cat Advanced Cabin Filtration System (ACF) uses a precleaner and self-cleaning, high-efficiency filtration system to deliver fresh, clean air to the machine’s HVAC system. In any application demanding superior operator protection, ACF has the strength to remove harmful particulates from cabin airflow. ACF offers filtration options to cover regulated particulate and gas environments. This includes exposure regulations from the Mine Safety and Health Administration (MSHA), OSHA (Silica Rule Table 1), European Union, South America and Australia. Cat high efficiency filters and HEPA/H13 filters help protect against respirable dust, including:

Respirable crystalline silica (RCS)

Diesel particulate matter (DPM)

Asbestos

Beryllium

Lead

Combustible smoke

Bacteria

Activated carbon and ABEK1 carbon filtration options are also available.

ACF Upgrades And Retrofits

Some Cat machines can include ACF. It can also be retrofitted on other heavy equipment, not limited to Cat machines.

In addition, your local Cat dealer has replacement filters readily available for the system to help you optimize health, safety and productivity. If you are unsure about which upgrades or retrofits you might need, your Cat dealer can help you determine your options.

ACF Is Easy To Maintain

When using ACF technology, HVAC filter changes can be less frequent. You will replace the filter when it becomes restricted and can no longer provide enough airflow to sustain cabin pressurization.

Precleaners can help reduce replacement frequency.

Less dust builds up on evaporators and heating coils, which can lead to better HVAC performance and reduced maintenance.

Cabin electronic equipment is also exposed to fewer contaminants, resulting in consistent performance and less maintenance.

Quick Tips For Cabin Air Filter Replacement

When it’s time to replace the cabin air filter, it’s important to take precautions that will avoid contamination during installation. You will find more detailed information in your Operation and Maintenance Manual (OMM), but keep the following tips in mind:

Handle the new filter element carefully.

Keep the filter in the original packaging until ready to install to limit its exposure to open air and the introduction of dirt or contaminants.

Inspect the filter to make sure it is not damaged.

Once installed, check that the filter is well seated and sealed properly against its housing.

Do not tap filters on hard surfaces to remove dust. This can damage the filter, and reducing the dirt layer may reduce efficiency.

For more information about protecting the air quality in your equipment cabin, talk to your Cat dealer. Need replacement Cat filters or other parts? Shop now.

Frequently Asked Questions

Q: Can I replace the cabin air filter?

A: Yes, this is a simple maintenance task you can do. Here’s how to do Cat cab filter maintenance.

Q: How often should I change the cab air filter?

A: Replace filters only when airflow is restricted or cabin pressurization can’t be maintained. Using ACF technology helps reduce how often filter changes are needed.

Q: What is the best cabin air filtration system for heavy equipment?

A: The Cat Advanced Cabin Filtration System (ACF) offers high efficiency filters, plus carbon options, to meet safety standards.

Q: Can I retrofit advanced filtration on older machines?

A: Yes. Cat ACF can be retrofitted to most heavy equipment with dealer support.